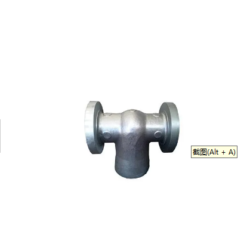

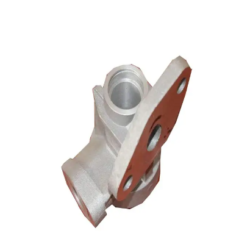

As a leading Valve body manufacturer, we provide a wide range of high-quality products that are tailored to meet the unique needs of our clients. Our Valve body process produces precise and intricate parts with excellent surface finishes, making it a popular choice for industries that demand quality and precision, such as aerospace, medical, and automotive. With our commitment to quality and customer satisfaction, we are confident that our Valve body solutions will meet your needs and exceed your expectations. If you’re looking for a reliable and efficient Valve body manufacturer, look no further than us. Contact us today to learn more about our products and services!

Dongying Casting: A Deep Dive into a Manufacturing Powerhouse

Dongying, a city located in the northeastern part of Shandong Province, China, has emerged as a significant player in the global casting industry. With a rich history, advanced manufacturing techniques, skilled workforce, and modern infrastructure, Dongying has earned its reputation as a casting powerhouse.

Historical Foundation: The roots of Dongying’s casting industry date back centuries. The city’s strategic location along the Yellow River and its proximity to natural resources like coal and iron ore contributed to the early development of metalworking skills. These foundational skills laid the groundwork for the evolution of Dongying’s casting industry.

Diverse Casting Techniques: Dongying’s casting industry encompasses a wide range of techniques, each serving specific industrial needs. Investment casting, also known as precision casting, is a cornerstone of the city’s capabilities. This intricate process involves creating wax patterns, forming ceramic molds around them, melting out the wax, and finally pouring molten metal into the mold. The result is highly detailed and complex parts that find applications in aerospace, automotive, and medical fields.

Sand casting, another prominent technique, involves creating molds using sand and a binder. This approach is versatile and cost-effective, making it suitable for producing large and irregularly shaped components. Dongying’s expertise in sand casting contributes to its ability to provide various industries with durable and reliable parts.

Precision molding, a newer technique, combines elements of traditional casting with modern manufacturing technologies. It allows for the rapid production of complex and accurate parts, often with reduced post-processing requirements. This technique has opened up new avenues for Dongying’s casting industry, enabling it to stay at the forefront of technological advancements.

Skilled Workforce: At the heart of Dongying’s casting success is its skilled workforce. The city has cultivated a tradition of craftsmanship, with generations passing down casting techniques and knowledge. Today, Dongying’s casting professionals undergo rigorous training to master the intricacies of different casting methods. Their expertise in pattern-making, mold preparation, metal pouring, and finishing contributes to the production of high-quality cast components.

Modern Infrastructure: Dongying’s commitment to industrial development is evident in its modern infrastructure. The city has invested significantly in casting facilities, research and development centers, and quality control laboratories. These investments have propelled Dongying’s casting industry into the modern era, enabling it to meet global demands for precision, efficiency, and reliability.

Global Impact: Dongying’s casting industry has a substantial impact on both local and global economies. The city’s output of cast components fuels various sectors, including automotive, aerospace, energy, and machinery. The high-quality components manufactured in Dongying are used in critical applications, where precision and durability are non-negotiable.

Environmental Considerations: As the world increasingly focuses on sustainability and environmental responsibility, Dongying’s casting industry has also taken steps to minimize its ecological footprint. Efforts to reduce energy consumption, optimize material usage, and implement eco-friendly manufacturing processes are underway. These initiatives not only align with global environmental goals but also ensure the long-term viability of the industry.

Challenges and Future Outlook: Despite its success, Dongying’s casting industry faces challenges common to manufacturing sectors worldwide. The industry must continuously adapt to evolving market demands, technological advancements, and regulatory changes. Ensuring a steady supply of skilled workers and fostering innovation remain critical priorities for Dongying’s casting industry to maintain its competitive edge.

Looking ahead, Dongying’s casting industry is poised for growth. The city’s commitment to research and development, combined with its skilled workforce and advanced manufacturing capabilities, positions it well to capitalize on emerging trends such as additive manufacturing and smart manufacturing technologies.

In conclusion, Dongying’s casting industry stands as a testament to the city’s historical roots, technological prowess, and industrial resilience. From its humble beginnings to its current status as a global casting powerhouse, Dongying has navigated the challenges of modern manufacturing while retaining the craftsmanship that defines its core. As industries continue to evolve, Dongying’s casting industry remains a dynamic and essential player in the global manufacturing landscape.